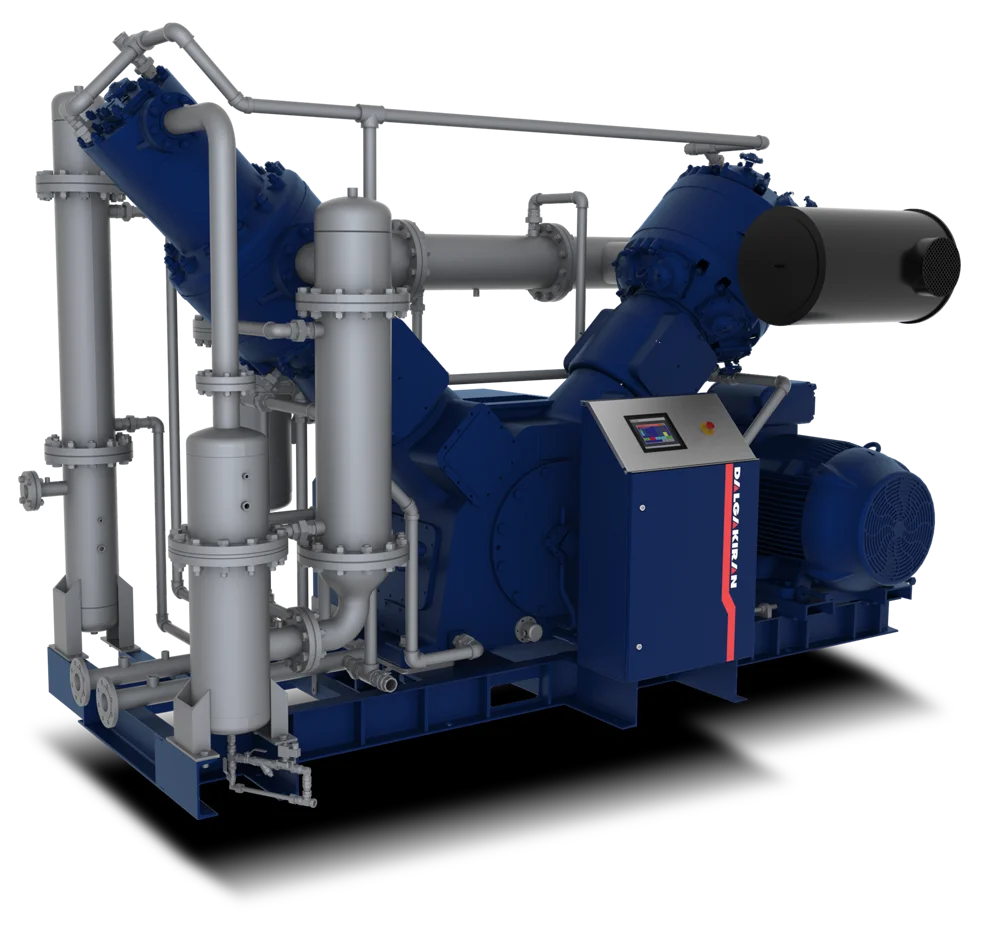

DALGAKIRAN PET MASTER Series are reliable and high performance oil free reciprocating air compressors used in the pet bottle blowing, food and health industries.

MODELS AND TECHNICAL INFORMATION

| Model | Pressure | Capacity | Motor Power | Connection Size | Dimensions (mm) | Weight | ||||

| bar | psi | m3/min | cfm | kW/HP | Length | Width | Height | kg | ||

| PET MASTER 50 | 40 | 580 | 3.6 | 127 | 37/50 | G 1 1/4″ | 1669 | 3647 | 2395 | 5500 |

| PET MASTER 75 | 40 | 580 | 5.5 | 194 | 55/75 | G 1 1/4″ | 1669 | 3647 | 2395 | 5500 |

| PET MASTER 100 | 40 | 580 | 7.4 | 261 | 75/100 | G 1 1/4″ | 1744 | 3673 | 2470 | 6500 |

| PET MASTER 125 | 40 | 580 | 9.1 | 321 | 90/125 | G 1 1/4″ | 1744 | 3673 | 2470 | 6500 |

| PET MASTER 150 | 40 | 580 | 11.6 | 410 | 110/150 | G 2″ | 1977 | 4192 | 2814 | 7500 |

| PET MASTER 180 | 40 | 580 | 13.5 | 477 | 132/180 | G 2″ | 1977 | 4192 | 2814 | 7500 |

| PET MASTER 220 | 40 | 580 | 16.4 | 579 | 160/220 | G 2″ | 1977 | 4192 | 2814 | 7800 |

| PET MASTER 270 | 40 | 580 | 21.3 | 752 | 200/270 | G 2″ | 2203 | 4234 | 2841 | 9200 |

| PET MASTER 300 | 40 | 580 | 23 | 812 | 220/300 | G 2″ | 2203 | 4234 | 2841 | 9200 |

| Model | Pressure | Minimum Capacity | Maximum Capacity | Motor Power | Connection Size | Dimensions (mm) | Weight | |||||

| bar | psi | m3/min | cfm | m3/min | cfm | kW/HP | Lenght | Width | Height | kg | ||

| PET MASTER 75 VSD | 40 | 580 | 4.1 | 145 | 5.5 | 194 | 55/75 | G 1 1/4″ | 1811 | 3533 | 2403 | 5600 |

| PET MASTER 125 VSD | 40 | 580 | 6.8 | 240 | 9.1 | 321 | 90/125 | G 1 1/4″ | 1812 | 3550 | 2431 | 6650 |

| PET MASTER 180 VSD | 40 | 580 | 10.1 | 357 | 13.5 | 477 | 132/180 | G 2″ | 1975 | 4168 | 2814 | 7750 |

| PET MASTER 220 VSD | 40 | 580 | 12.3 | 434 | 16.4 | 579 | 160/220 | G 2″ | 1975 | 4168 | 2814 | 8000 |

| PET MASTER 300 VSD | 40 | 580 | 17.3 | 611 | 23 | 812 | 220/300 | G 2″ | 2212 | 4223 | 2840 | 9500 |

General Information

PET MASTER Series is specially designed for PET bottle blowing industry

Because oil is not used in the compaction section, it produces 100% oil-free air

Electro-pneumatic flow control available

The compressor discharge system is provided by holding the suction valves in the open position

PLC control unit provides easy and safe use thanks to warning and safety functions

Acuple design provides ease of installation and installation.

The integrated electrical system provides user-friendly operation

Condensate output is made from a single point for easy installation

Possibility to see operating parameters via controller

High cooling efficiency and low operating temperature ensure long service life and extended service life

The large body and low speed operation feature reduce the workload of the compressor. Service intervals on this count increase and component life increases

On-demand co-aging system and compressors can work together and at the same level, reducing service frequency.