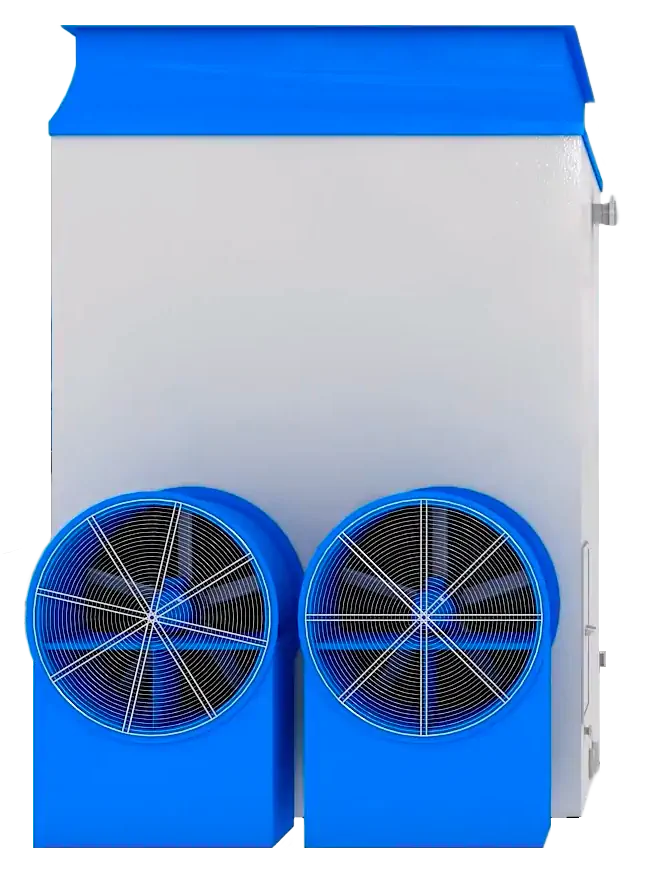

Designed for smaller capacities, MFK model cooling towers are designed to provide optimum cooling. In MFK model towers, the fan is placed next to the tower.

Fan blades are made of PPG / PAG material and axial. As the fans are next to the tower, this fan group has ease of operation and maintenance.

MFK model towers are counter flow and forced drive. One motor and fan is used in MFK (3×3) and MFK (4×4) model cooling towers. In other MFK models, two motors and fans are used.

Body panels used in tower construction are manufactured from FRP (Glass Reinforced Polyester) plates and are resistant to corrosion and have a very long service life. The inner and outer surface of the tower; It is a “Gel-Coat” material colored with polyester-based pigments, resistant to all weather conditions and UV rays, does not fade, do not deteriorate, does not require aesthetics and paint.

MODELS AND TECHNICAL INFORMATION

| Model | Widht (mm) | Lenght (mm) | Height (mm) | Water inlet height (mm) | Water inlet-outlet diameter (mm) |

| MFK 3×3 | 900 | 900 | 2.500 | 2.000 | 90 |

| MFK 4×4 | 1.200 | 1.200 | 3.050 | 2.625 | 90 |

| MFK 4×6 | 1.200 | 1.800 | 3.150 | 2.505 | 110 |

| MFK 6×6 | 1.800 | 1.800 | 3.150 | 2.930 | 160 |

| MFK 6×8 | 1.800 | 2.100 | 3.450 | 2.930 | 160 |

| MFK 8×8 | 2.100 | 2.100 | 3.450 | 2.930 | 160 |

| Model | Dry tower weight (kg) | Working tower weight (kg) | Nominal motor power (kW) | 40 / 30 / 24 °C | 35 / 30 / 25 °C | ||

| Capacity (kcal/h) |

Water flow (m/h3) |

Capacity (kcal/h) |

Water flow (m/h3) |

||||

| MFK 3×3 | 160 | 420 | 1,1 | 110.000 | 11 | 75.000 | 15 |

| MFK 4×4 | 210 | 650 | 2,2 | 200.000 | 20 | 135.000 | 27 |

| MFK 4×6 | 305 | 1.060 | 2 x 1,5 | 300.000 | 30 | 200.000 | 40 |

| MFK 6×6 | 400 | 1540 | 2 x 2,2 | 460.000 | 46 | 300.000 | 60 |

| MFK 6×8 | 550 | 1.540 | 2 x 3 | 650.000 | 65 | 415.000 | 83 |

| MFK 8×8 | 740 | 2.750 | 2 x 4 | 760.000 | 76 | 500.000 | 100 |

General Information

- Vinylester

- Flame Retardant Polyester

- Polyester

- PP Bigugi

- PVC Film

- PP Splash Type

- PVC C type

- PVC Cellulat type

- PVC C Type

- PVC Cellular Type

- Aluminum

- PPG/PAG

- Silent Fan